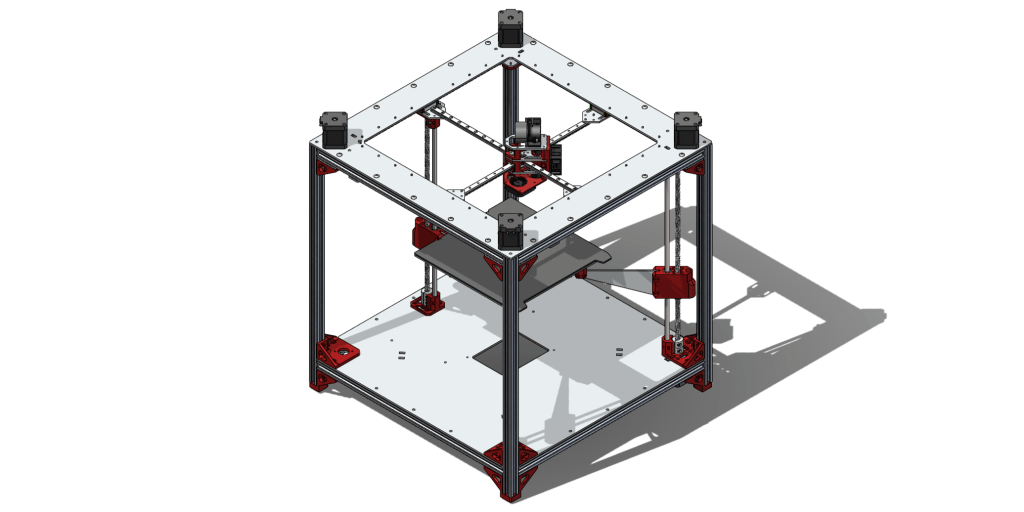

Corvus is my most technical, complex, and expedited project to date. This was designed and assembled in just 4 weeks. After a decade of 3D printing experience, I finally designed my own from the ground up. This was my last cry against the innovations of Bambu Labs. My rage against the dying of the light.

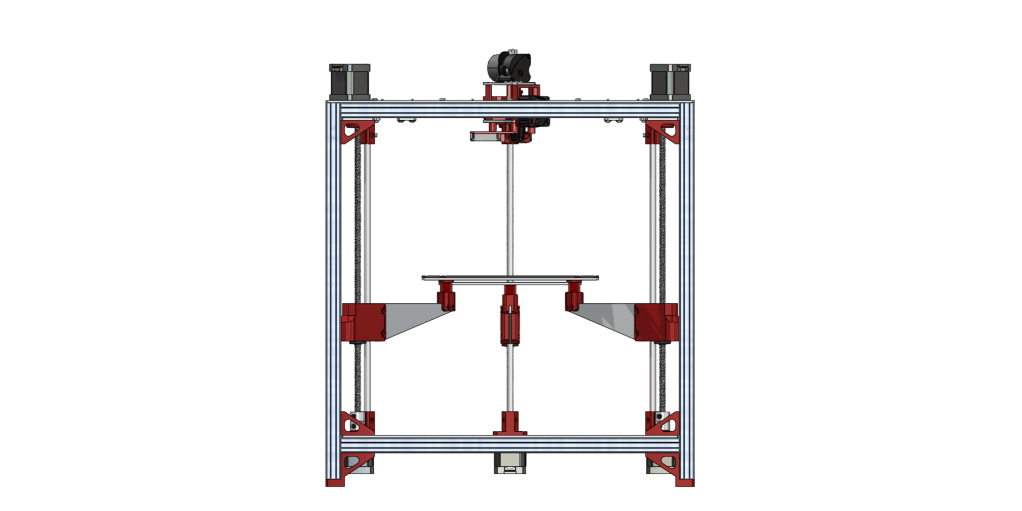

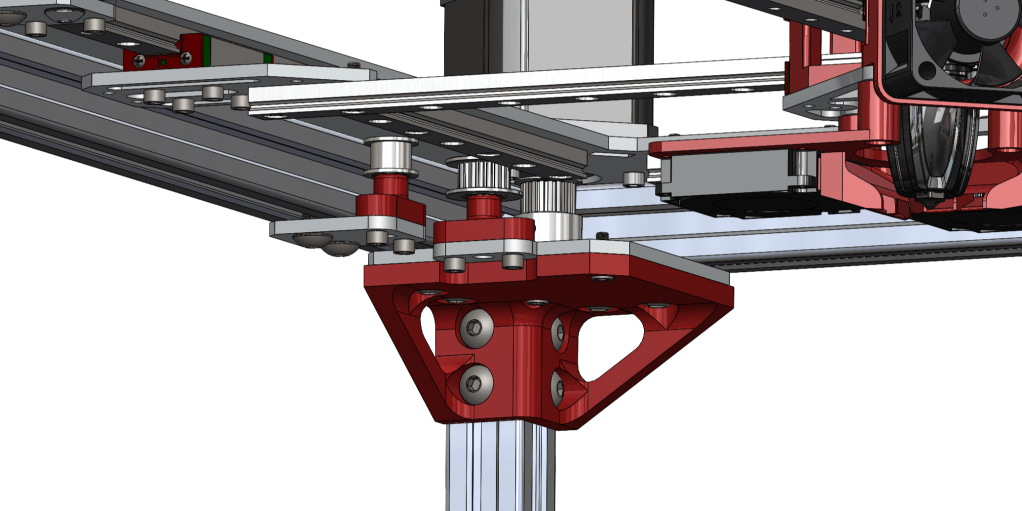

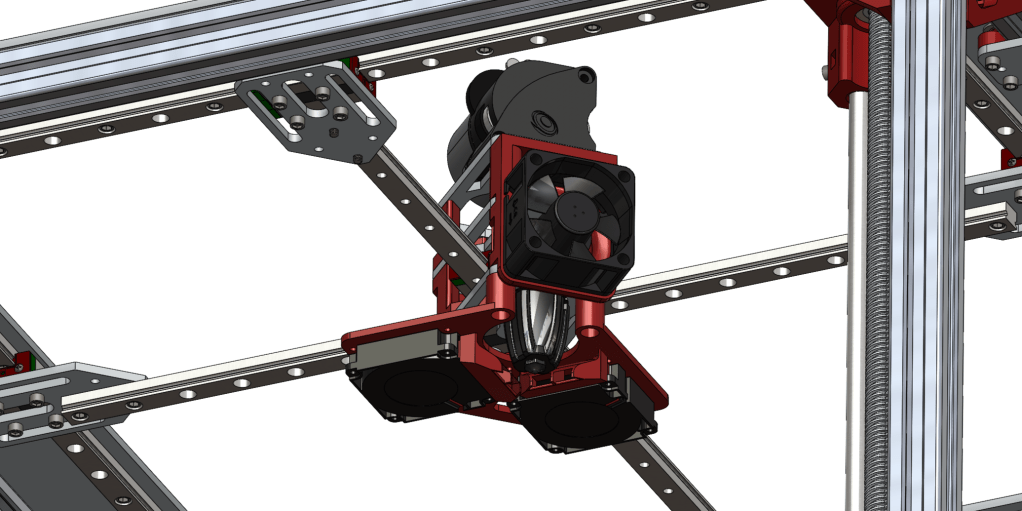

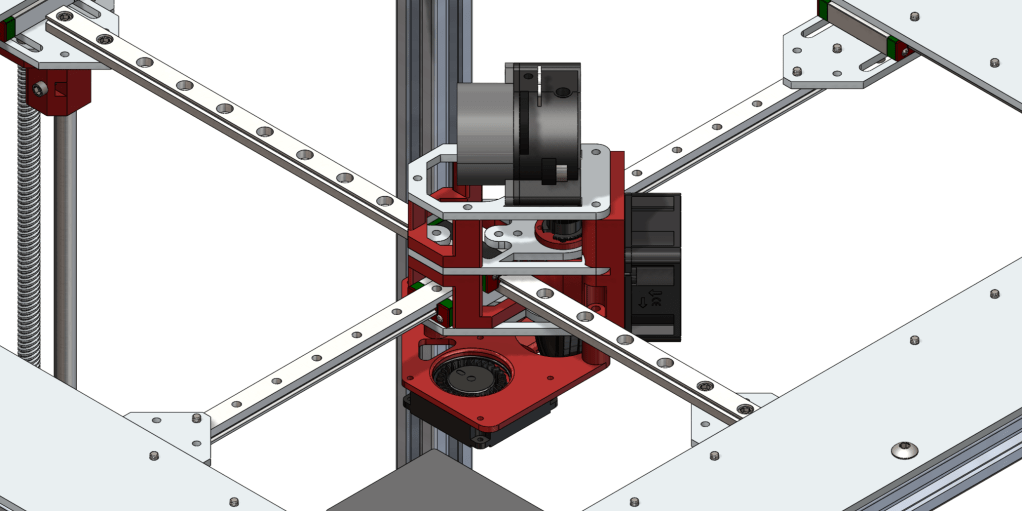

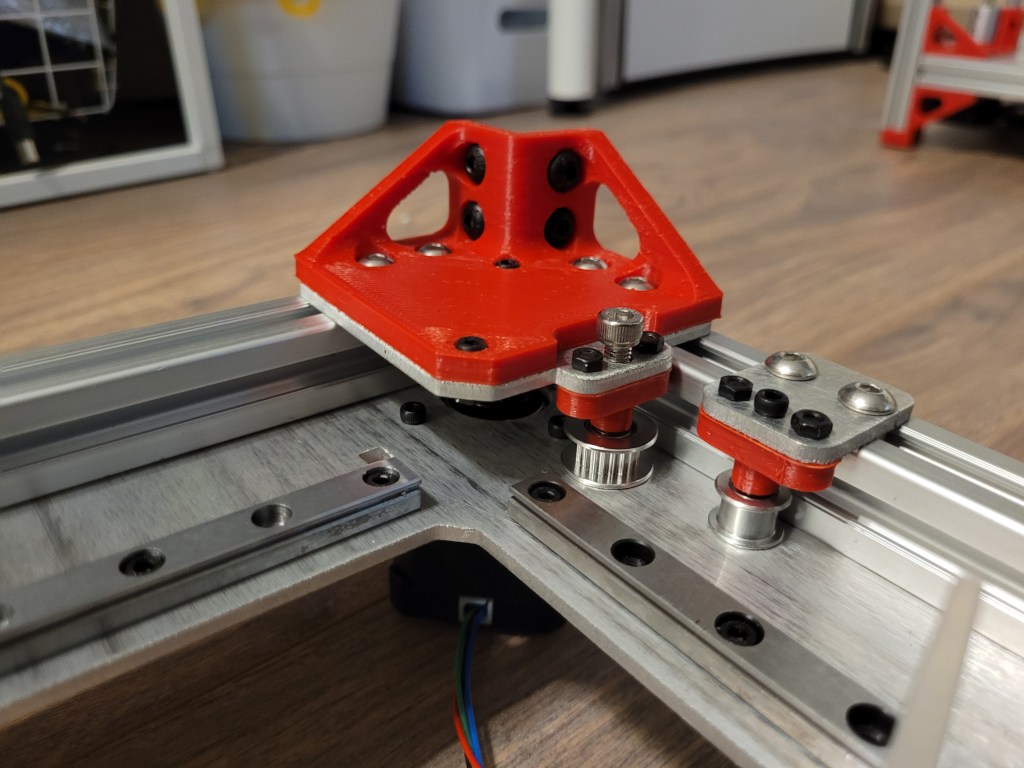

The XY Carriage weighed under 300g including a high torque direct drive extruder and a high flow Rapido hotend. The key to this success was the use of three lightweight custom brackets, enabling high rigidity with low mass.

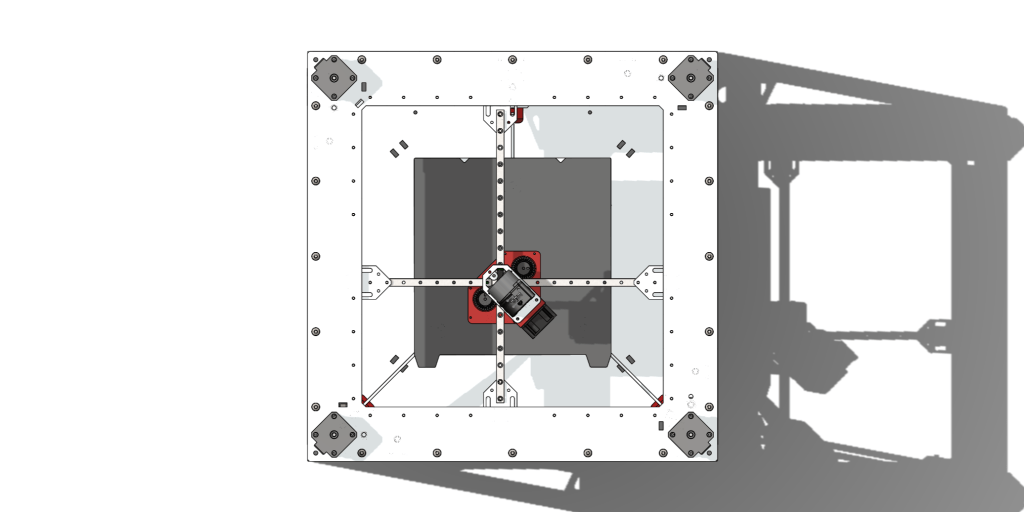

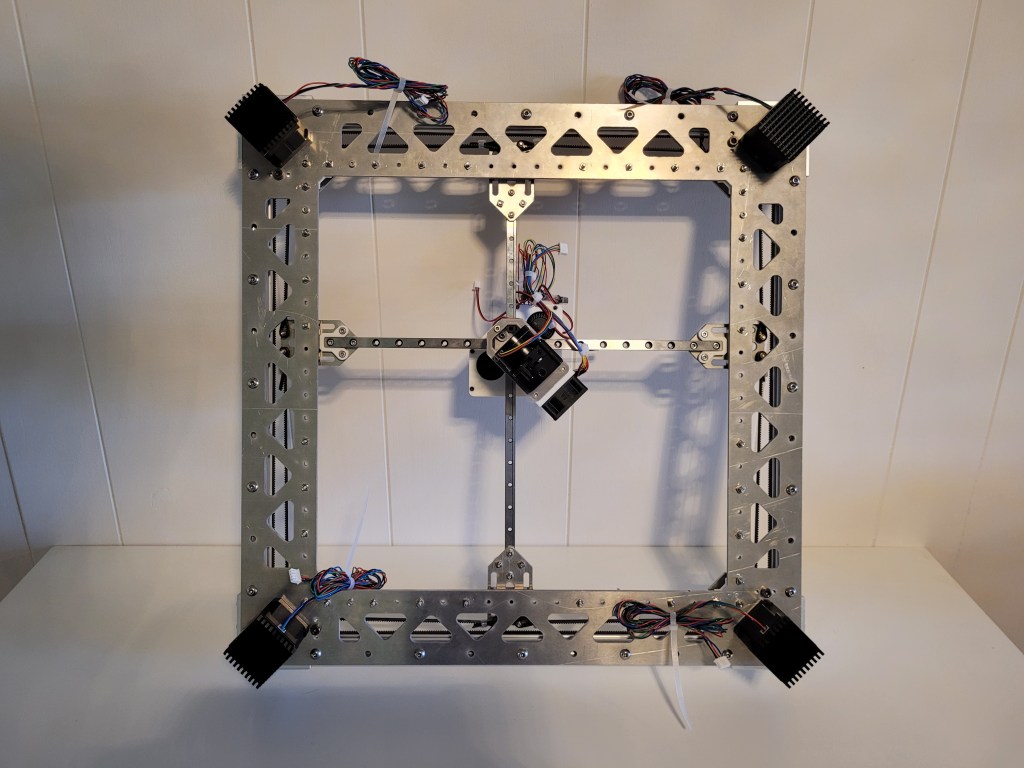

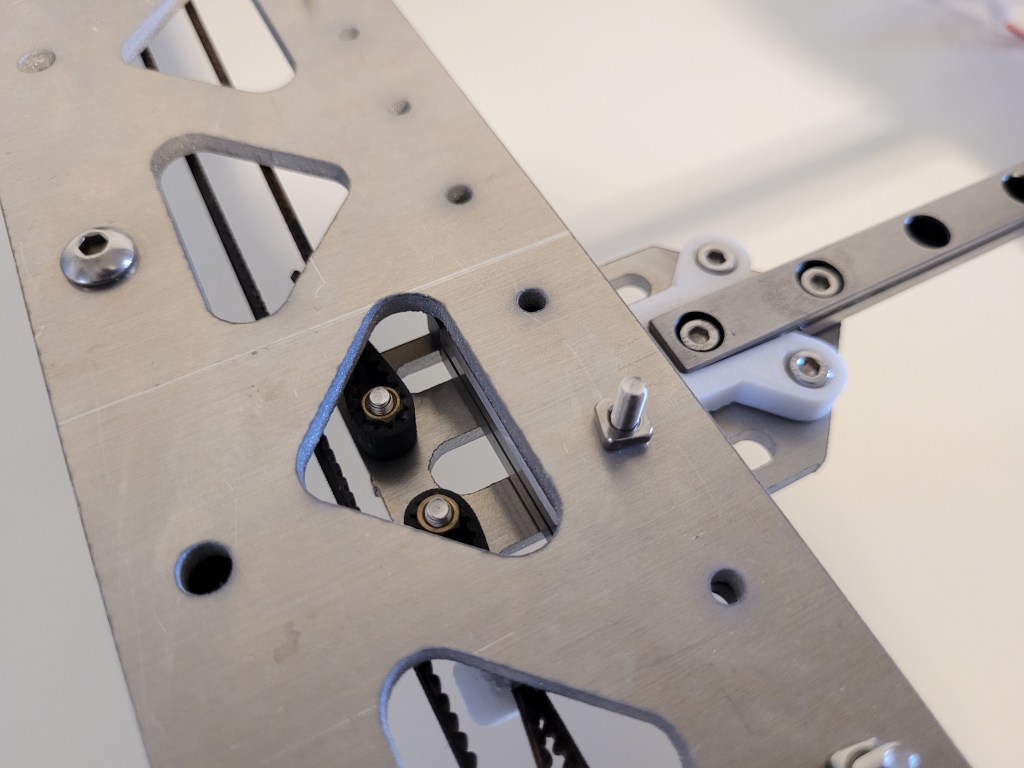

The X and Y axis of this CoreXY were made of lightweight custom 6061 brackets mounted on either side of a linear rail. Steel or Carbon rods are commonly used, but the latter is too heavy (and less stable due to concentric mounting require for rod bearings, rather than the tapped holes in linear rails), and the former is not rigid enough in this architecture.

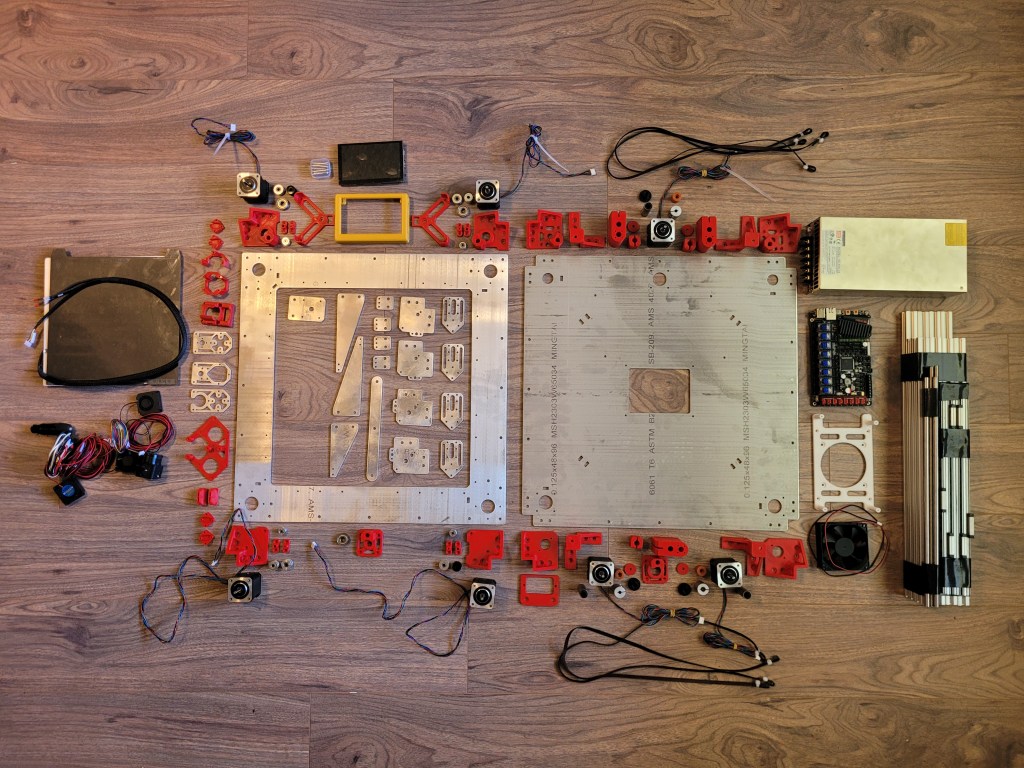

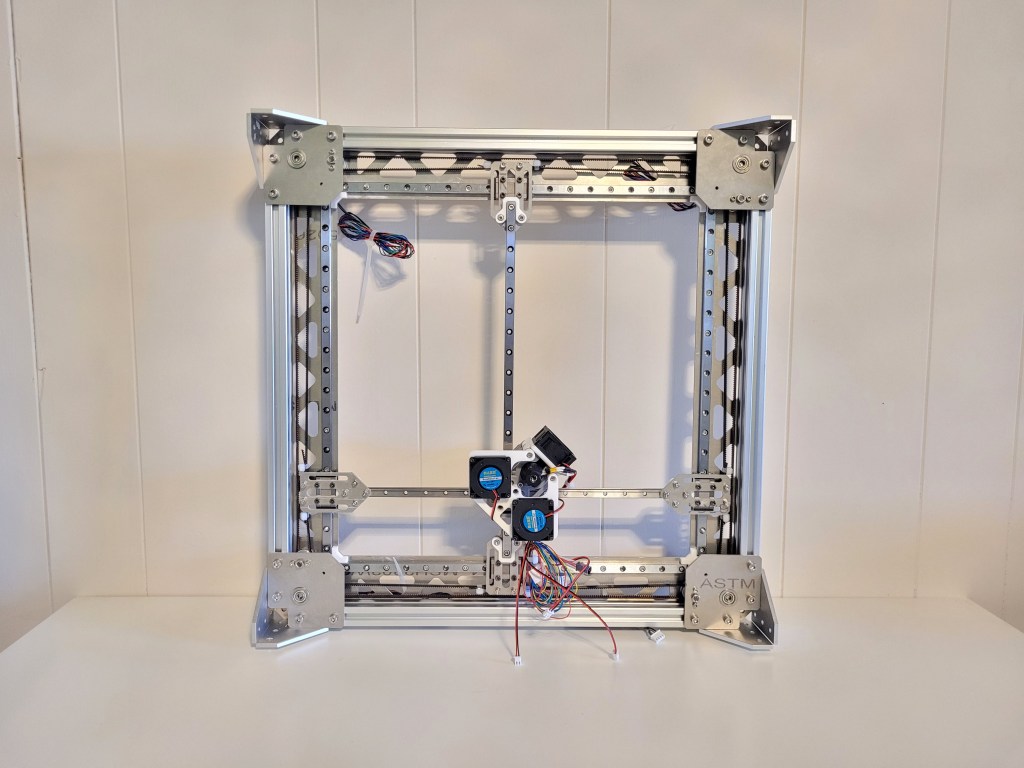

The frame, and brackets, were manufactured at UBC machine shops and Xometry. The use of an aluminum frame for the top and bottom ensured a square and plane design (as linear rails, bearings, and motors were all bolted directly into this frame).

This is key to high velocity performance, as the slightest misdirection, even by 100 microns across an axis, can cause inaccuracies far larger in prints, as well as mechanical wear, noise, or worse.

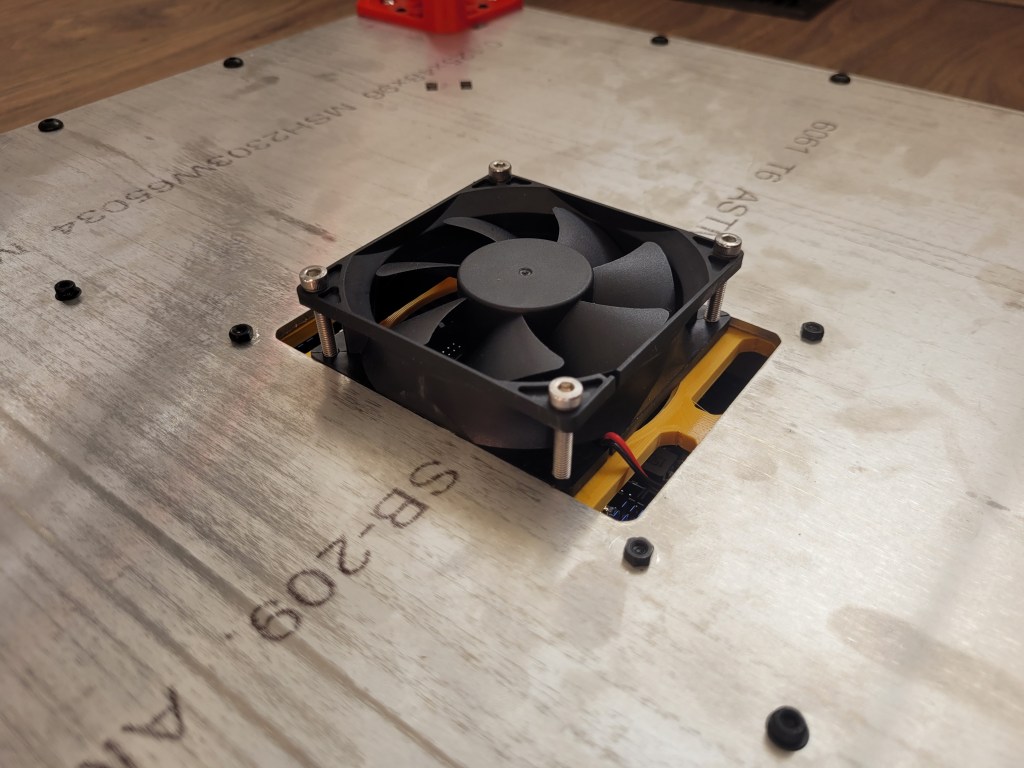

An entire metal frame also allowed the capability of printing PEEK with a proper enclosure design and water-cooling of the extruder motor and hotend. This is also why the motors were mounted outside of the print volume.

Any robust design requires a very tried-and-true tests, such as jumping and standing on top.

XY rails – Controller Board Cooling – XY bearings and ASA frame bracket.

Leave a comment