Stoodis is a 5-inch diameter HPR designed to handle a 75mm solid Aerotech motor, adapted for use with a 54mm motor for NASA’s First Nation Launch competition.

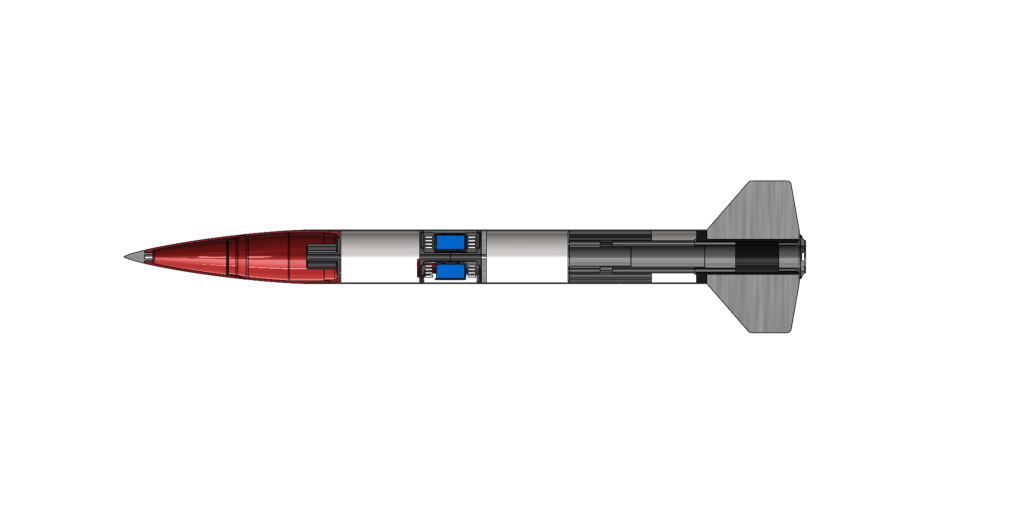

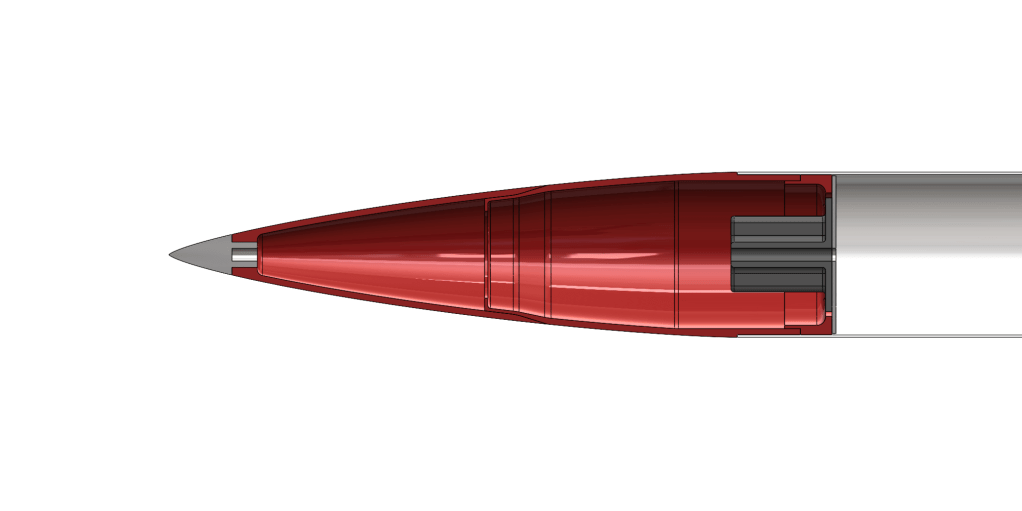

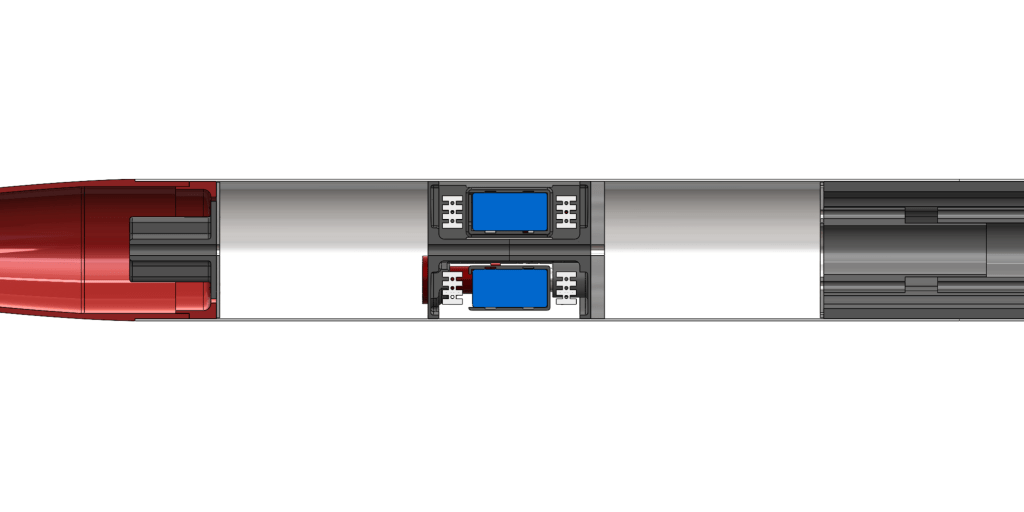

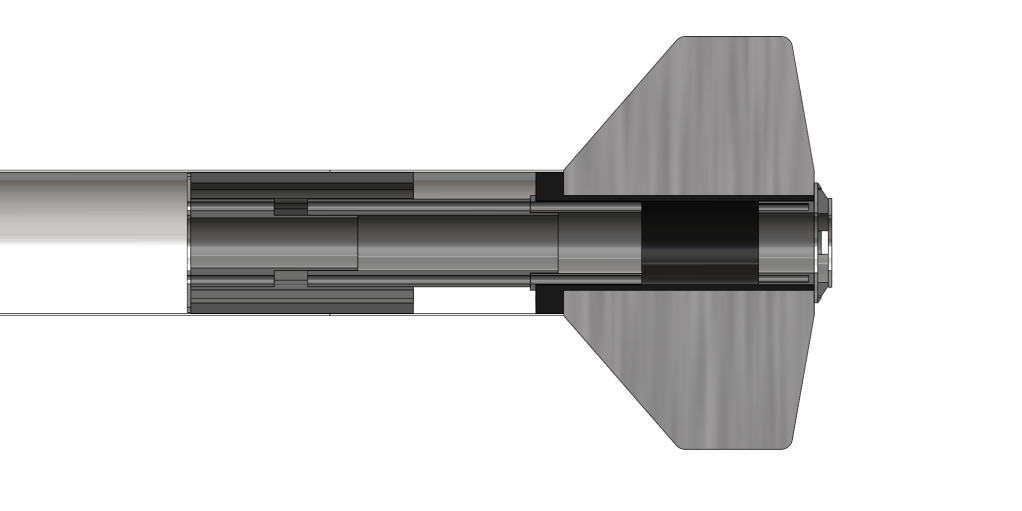

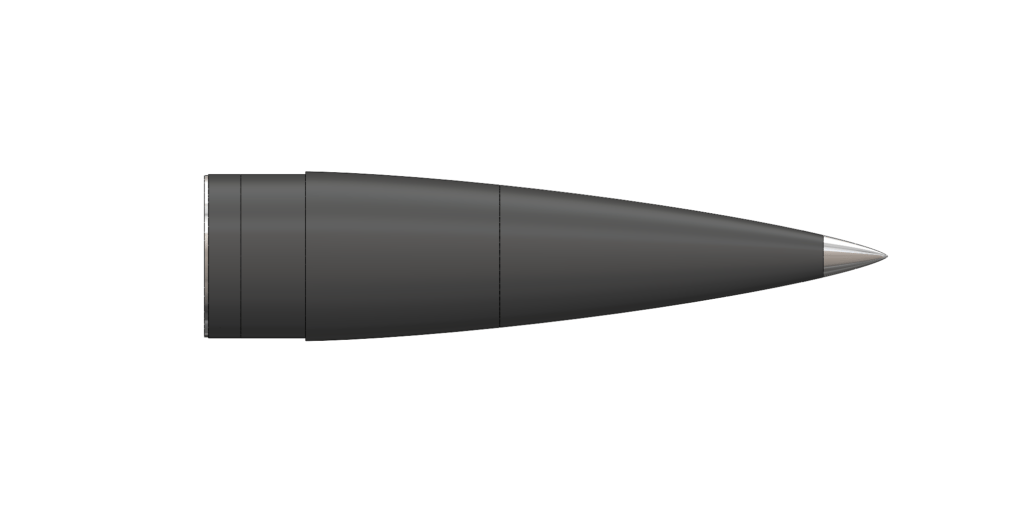

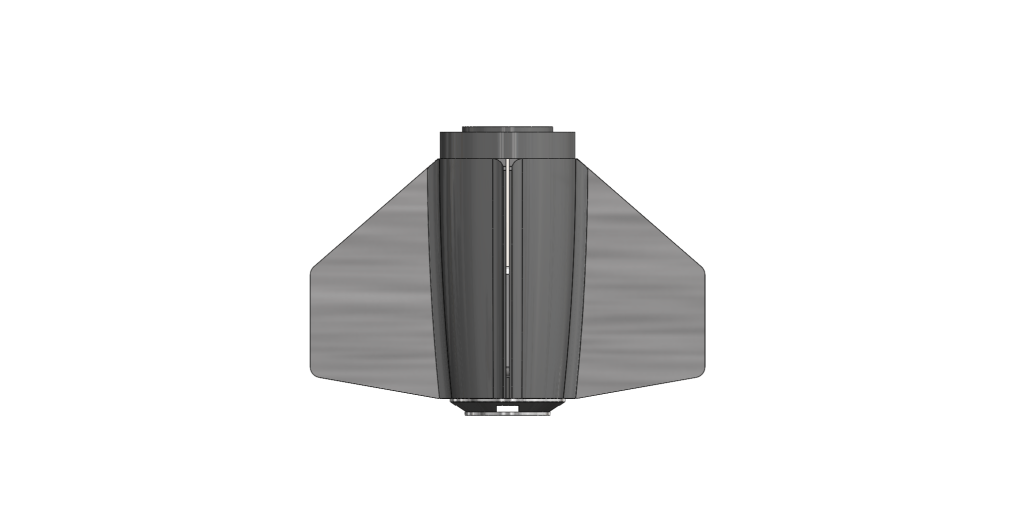

This rocket involved 3D Printing of PA6GF (for the avionics to allow GPS and Radio communications) and PA612CF (for the nosecone, bulkheads, couplers, and fincan due to its high modulus and low density) as well as Waterjet cutting of 6061-T6 Aluminum (for the plates and fins due to stiffness) and CNC machining of a nosecone tip (to protect the nosecone during launch from heat, during descent from collisions with ground, and as securement for a threaded rod running to an eyenut and parachute).

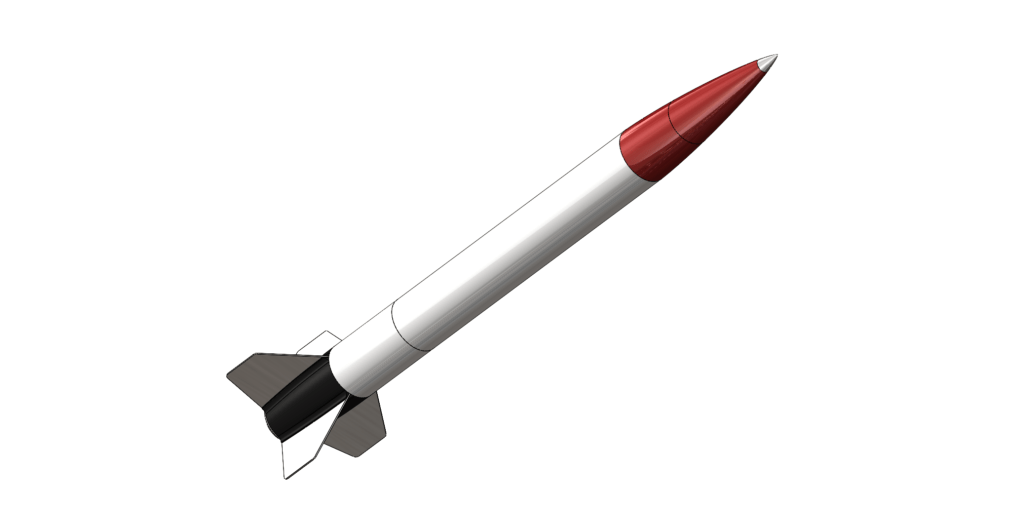

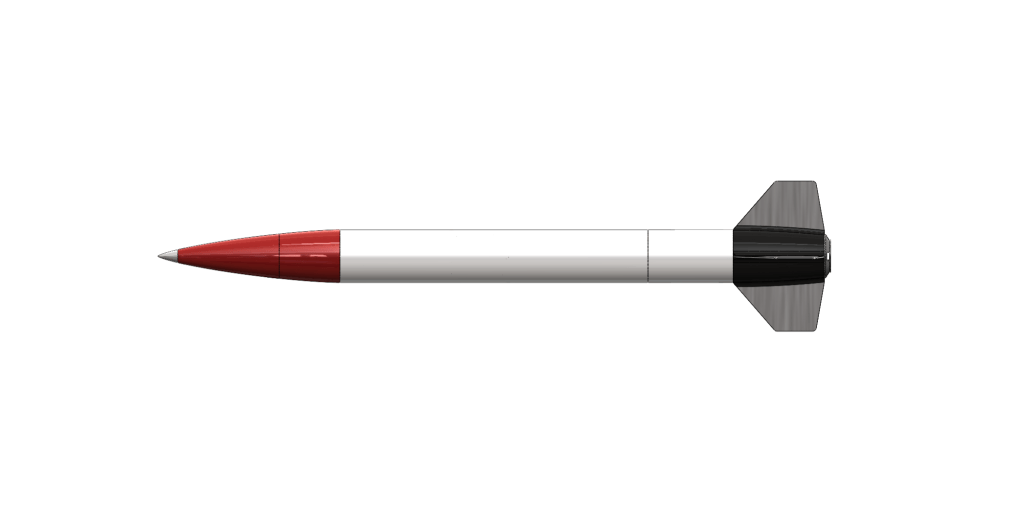

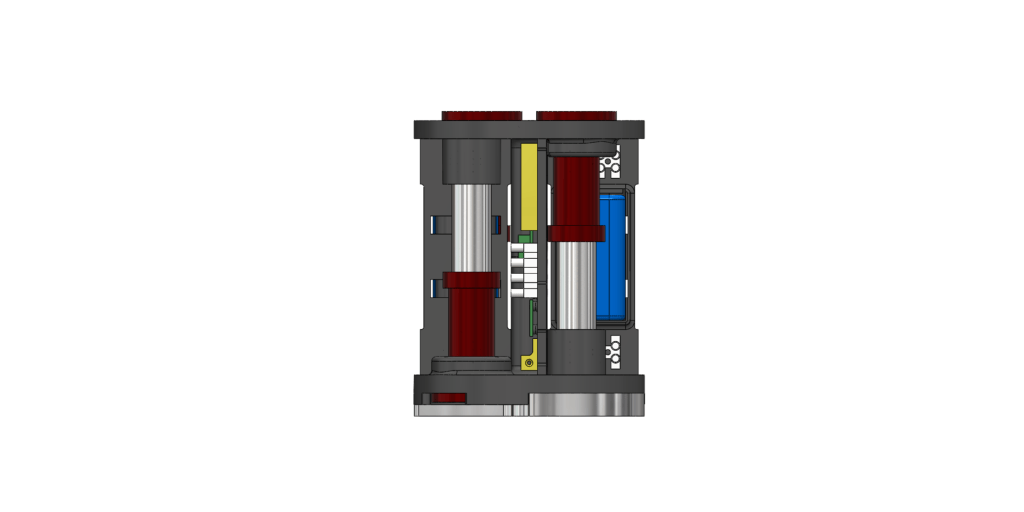

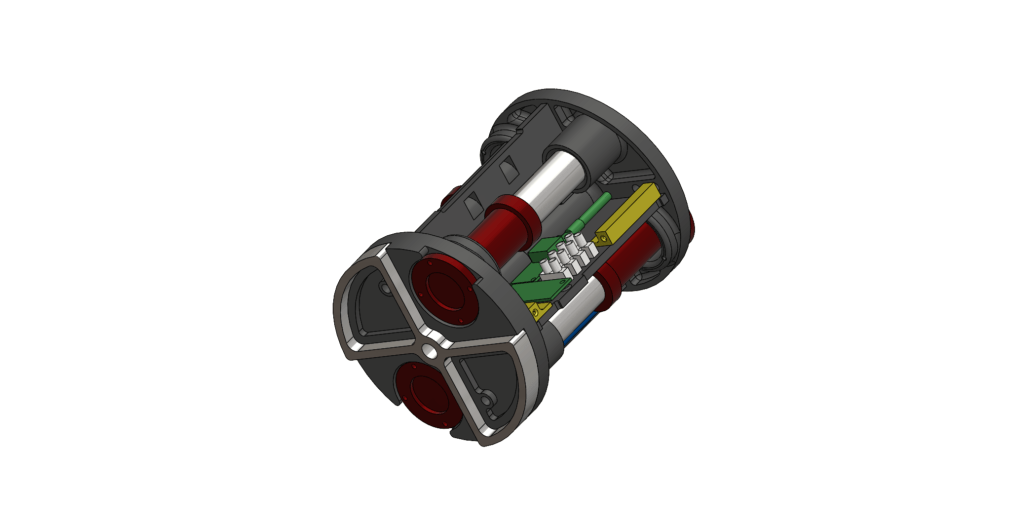

Above are multiple screenshots of my Solidworks design, including the full rocket, nosecone with electronics payload, avionics bay within the bodytube, fincan and engine ejection/adapters, and more in-depth views of the individual assemblies.

This design took 3 weeks to complete, with 1 of those weeks for the avionics bay alone; as I was in school and completing Capstone, it was a challenge juggling the complete CAD and Manufacturing of two simultaneous projects.

Above is an image of my Engineering Design Team holding Stoodis before out launch in Kenosha, WA.

This rocket flew above 3000ft from a K535W Aerotech Motor and was recovered only 50 metres from the launchpad (in fact, one of our team members caught the nosecone before it hit ground)

Above are some images of Stoodis throughout its development. I received much assistance in sanding, painting, and polishing (which always takes more time than planned for glossy finishes).

Stoodis is an example of a fast-paced project with high-stakes; after Launch is initiated, all one can do is watch and pray; pray that robust engineering and manufacturing withstands the roughest test — and it did.

Leave a comment