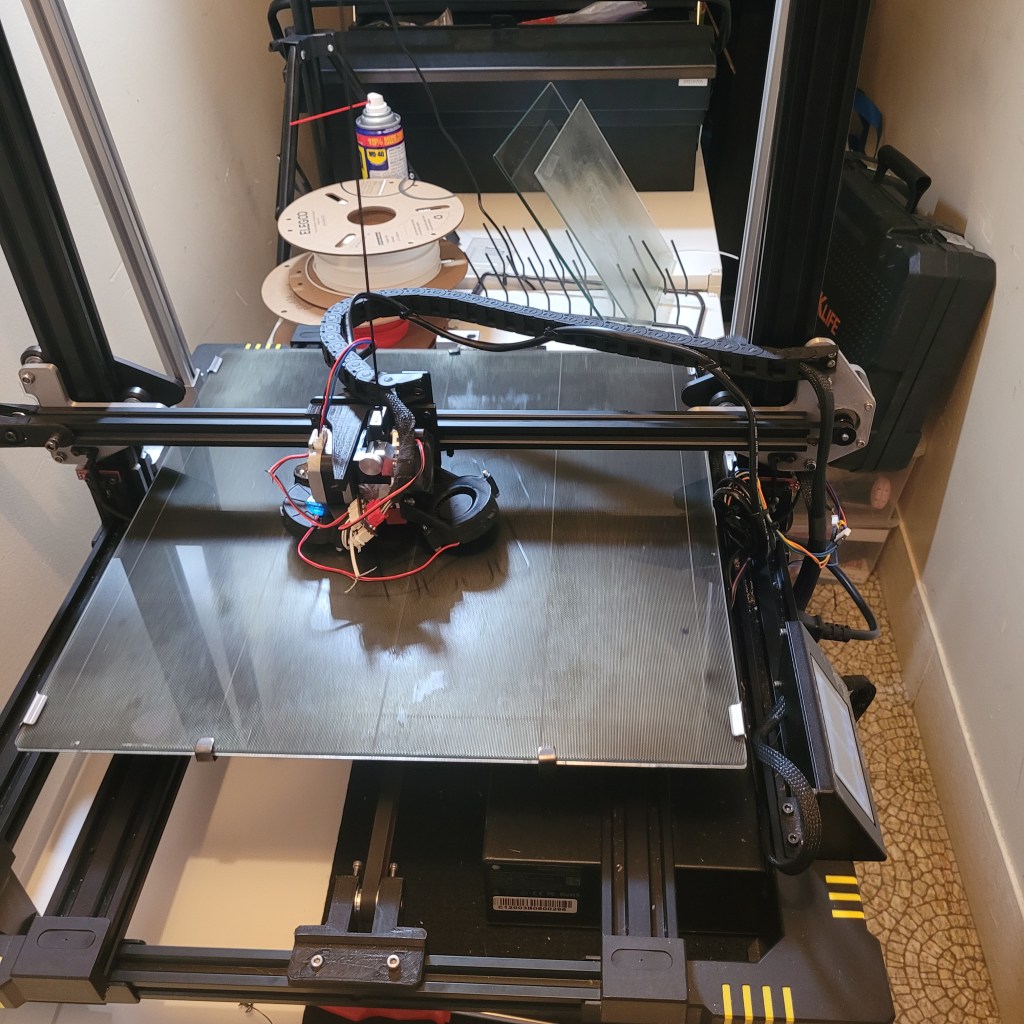

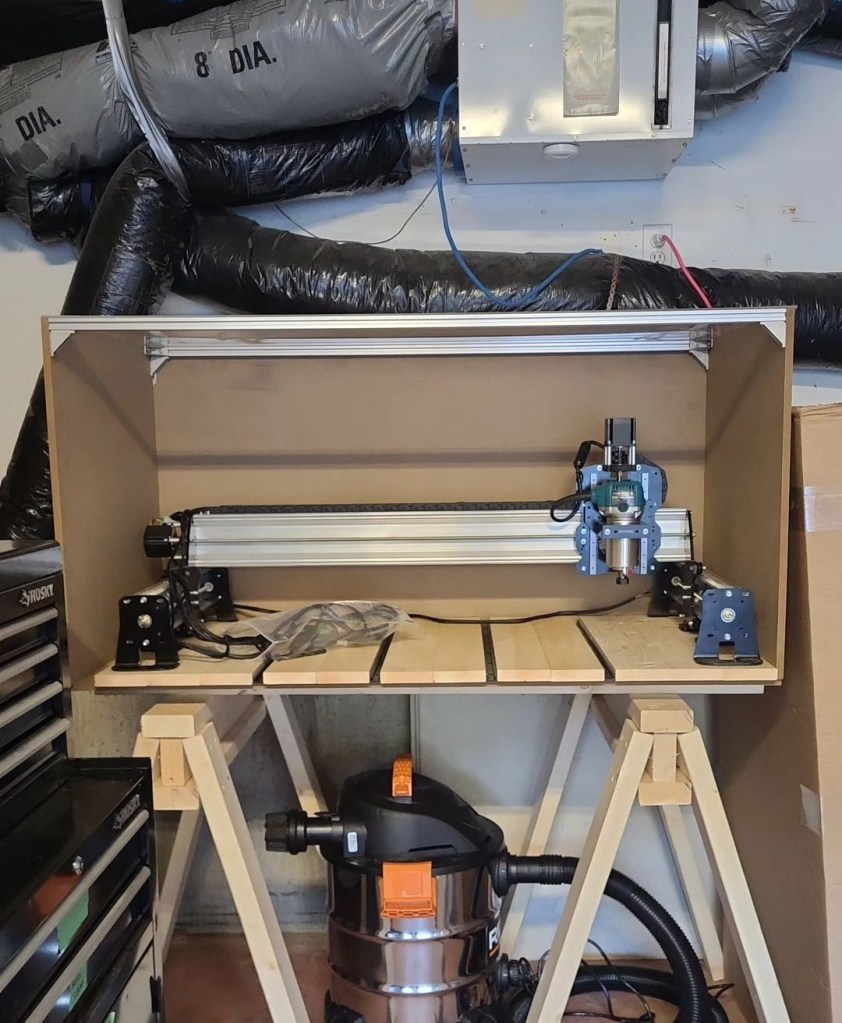

At the age of 12 I built my first 3D Printer. In the time since, I have built 7 more, a CNC Router, and have used SLA Printing, Waterjet cutting, 5-axis CNC machining, and 3D Scanning.

I believe that the removal of constraints in Manufacturing causes a direct affect through the entire Ideation process, removing constraints to Ideas themselves, and forming new ones, that were previously impossible to access or create.

It is not about advancing what we can make, but what we can imagine.

I currently own a Bambu Lab X1E (printing PA6GF and PA12CF), Scienci Longmill MK2 (soft and hardwoods), and Revopoint Miraco Scanner (complex geometry replication), amongst many other tools and devices.

I have experience in designing for CNC machining and using G-code or CAM, 3D Printing with Cura, Pre Form, Prusa slicer, and Bambu Studio.

I have used Blender and Fusion 360 for CAD, although the majority of my experience is in Solidworks. I also have work experience in Revit and AutoCAD.

I can replicate almost any design with a pair of calipers alone; I trust empirical measurements more than a scan unless there are detailed ornamental surfaces.

Feel free to email ravencaron@live.ca